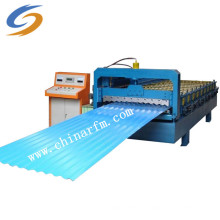

Wall and roof used galvanized roof sheet making machine

Basic Info

Model No.: TG-trapezidal

Product Description

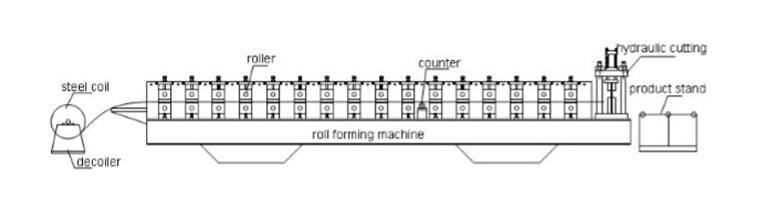

Manual De-coiler --- Electric Feeding --- Servo motor feeding ----oll Forming Machine------Computer Control Cabinet---Automatic cutting Mechanism ---Run-out Tables 3.Glazed Tile Rool Forming Machine equipment including

Manual De-coiler --- Electric Feeding --- Servo motor feeding ----oll Forming Machine------Computer Control Cabinet---Automatic cutting Mechanism ---Run-out Tables 3.Glazed Tile Rool Forming Machine equipment including 1 set | |

Hydraulic cutter | 1 set |

Electrical control system | 1 set |

Hydraulic system | 1 set |

Normal run out table | 3 PC 1m*1m |

Manual de-coiler | 1 set Max. loading 5 T |

(2) Glazed Tile Rool Forming Machine /Roll Forming Machine Colored Steel Roll Forming Machine

(2) Glazed Tile Rool Forming Machine /Roll Forming Machine Colored Steel Roll Forming Machine Steps | 15-17 steps |

Material of shaft | 45# steel hardening and tempering treatment |

Controlling system | PLC |

Motor Power | 4kw (Hydraulic station power:5.5kw ) |

Working speed (Forming speed) | 16-18 m/min (without cut time) |

Weight | about 5500kg |

plating chromium’s thickness | 0.05mm |

Main stand | 350# H steel welded structure Wall plate thickness: 14mm the main frame of machine is welded separately and the outside wall is connected by screw after being rot blasted on the surface |

(3) Hydraulic Cutting (4) Hydraulic station

(3) Hydraulic Cutting (4) Hydraulic station  (5) PLC Control System This system uses Delta PLC to control the all working actions. Production quantity and each piece length will be automatically measured. It is convenient to control the roll forming machine.

(5) PLC Control System This system uses Delta PLC to control the all working actions. Production quantity and each piece length will be automatically measured. It is convenient to control the roll forming machine.  (6) Product Rack (un-powered)

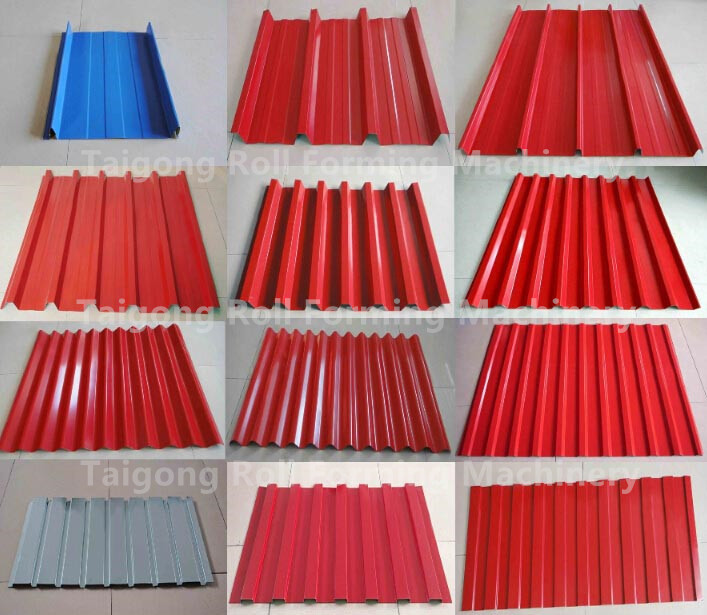

(6) Product Rack (un-powered)  (7). Products for Reference

(7). Products for Reference  Company Information

Company Information

Certifications

Certifications  Our Services 1) Guarantee period: 12 months limited warranty starting from date of delivery. Shipping cost for parts to be replaced during warranty period have to be borne by the customer. 2) Spare parts: bearings, buttons, chains, magnetic valve, protective tube etc. 3) Installation and training: A. If buyers visit our factory and check the machine, we will teach you how to install and us the machine, and also train your workers/technician face to face. B. Without visiting, we will send you user manual and CD to teach you to install and operate. C. COST OF INSTALLATION: The buyer should pay the installation charges (USD 80 one man one day). To the seller’s appointed account by T/T before the seller’s technicians go to the buyer’s factory. The buyer pays the seller’s technicians travel cost outside China, including round air tickets fee, accommodation and food, provide transportation from living hotel to the work place, necessary communication, and insurance, etc. If you have any further question of our Equipment, please feel free to contact me, thanks! Contact us if you need more details on Galvanized Roof Sheet Making Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Roof Sheet Making Machine、Sheet Making Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Our Services 1) Guarantee period: 12 months limited warranty starting from date of delivery. Shipping cost for parts to be replaced during warranty period have to be borne by the customer. 2) Spare parts: bearings, buttons, chains, magnetic valve, protective tube etc. 3) Installation and training: A. If buyers visit our factory and check the machine, we will teach you how to install and us the machine, and also train your workers/technician face to face. B. Without visiting, we will send you user manual and CD to teach you to install and operate. C. COST OF INSTALLATION: The buyer should pay the installation charges (USD 80 one man one day). To the seller’s appointed account by T/T before the seller’s technicians go to the buyer’s factory. The buyer pays the seller’s technicians travel cost outside China, including round air tickets fee, accommodation and food, provide transportation from living hotel to the work place, necessary communication, and insurance, etc. If you have any further question of our Equipment, please feel free to contact me, thanks! Contact us if you need more details on Galvanized Roof Sheet Making Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Roof Sheet Making Machine、Sheet Making Machine. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Color Steel Roof Roll Forming Machine > Trapezoidal Roof Roll Forming Machine

Premium Related Products