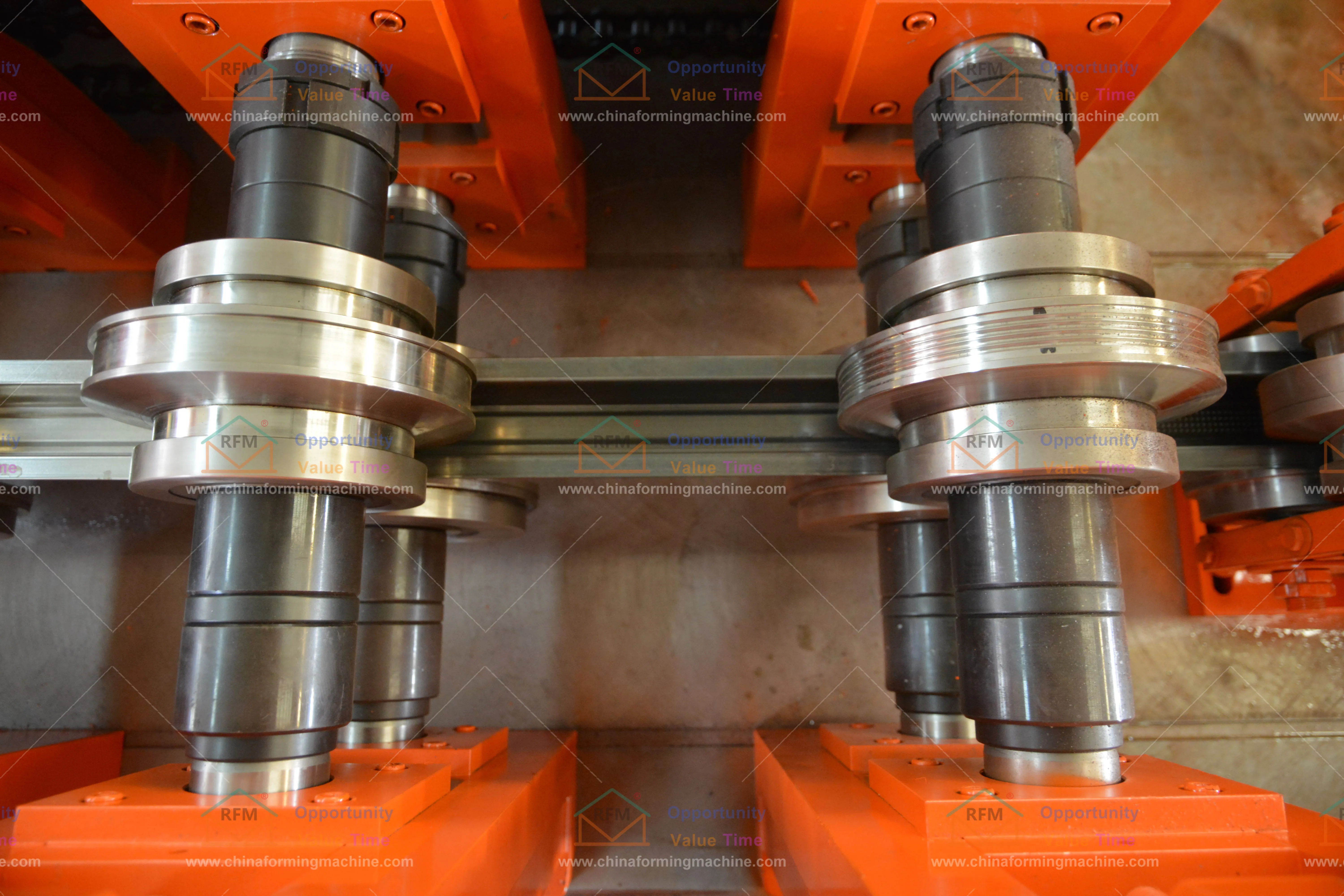

treatment.The hardness is around HRC 58-62℃.High quality rollers will help to produce the beautiful and high quality profile. That will satisfy your customers.

Using high qualiy thick shaft, the strength is more durable

After-sales Service Provided | Field maintenance and repair service, Video technical support |

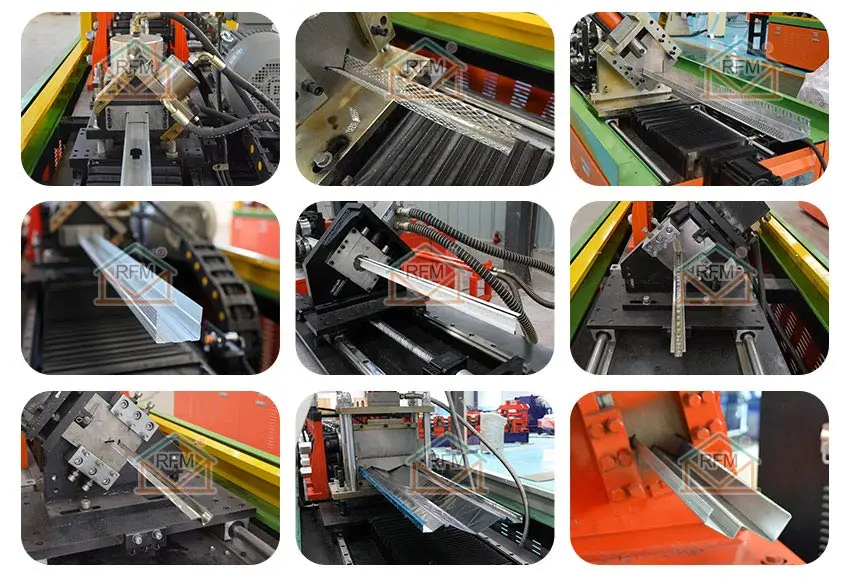

Name | machine manufacture omega profile drywall machine |

Thickness | 0.3-0.7mm |

Key Selling Points | automatic |

Roller Material | Cr12 with key-way |

Fine Machining | CNC Lathe after vacuum quenching |

Shaft material(Hard) | High grade 45# steel, heated and quenched, cylindrical grinding |

Shaft Diameter | Bearing steel,quenching and tempering |

Product Categories : C U profile keel forming machine > C U profile keel forming machine