PLC remote control customized automation shelf machine SHELF PANEL ROLL FORMING MACHINE

Product Description

PLC remote control customized automation Shelf Machine SHELF PANEL Roll Forming Machine

Machine attributes

After-sales Service Provided | Engineers available to service machinery overseas |

Raw material | Steel Coil GI PPGI |

Control system | PLC(imported Brand) |

Shafter material | 45# steel |

Roller Material | Gcr15 Steel with quenching |

Cutting blade material | cr12 with quenched treatment |

Color of Machine | Customer request |

Warranty | 2 years |

1. PRODUCTION PROCESS

The use of shelf equipment to produce shelf profiles, low production cost, high efficiency, environmentally friendly materials,

can be combined with production needs to manufacture automated production equipment, saving labor, making enterprises more

competitive in the fierce market competition.

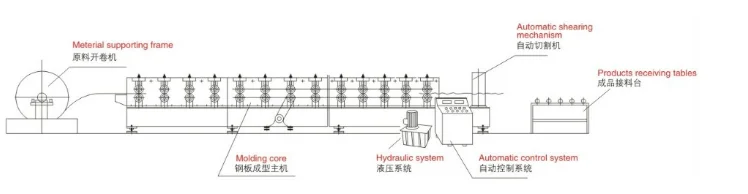

KINGREAL shelf equipment consists of: discharging, leveling, feeder, punching, forming machine, fixed length cutting, receiving

platform, electric control box (PLC control), etc.

The use of shelf equipment to produce shelf profiles, low production cost, high efficiency, environmentally friendly materials,

can be combined with production needs to manufacture automated production equipment, saving labor, making enterprises more

competitive in the fierce market competition.

KINGREAL shelf equipment consists of: discharging, leveling, feeder, punching, forming machine, fixed length cutting, receiving

platform, electric control box (PLC control), etc.

2. BRIEF INTRODUCTION

Brief introduction of LIMING Shelf System Roll Forming Machine:

Shelf roll forming equipment, shelf roll forming machine is widely used for cold roll forming of storage shelves, supermarket

shelves, heavy-duty shelves and other profiles.

Brief introduction of LIMING Shelf System Roll Forming Machine:

Shelf roll forming equipment, shelf roll forming machine is widely used for cold roll forming of storage shelves, supermarket

shelves, heavy-duty shelves and other profiles.

3. MACHINE FEATURES LIMING Shelving equipment features: 1. The machine adopts PLC full-range intelligent control, and the automation program is high, safe and efficient. 2. The forming frame is welded using high strength channel steel. High strength and long service life. 3. The material of the roll shaft is 40Cr, and the hardness is HB280 after quenching and tempering treatment. 4. The material of the molding die is GCr15, quenching treatment, hardness: HRC 56-62 °C. 5. The transmission structure is gearbox transmission or chain transmission.

Mainly include:

shelf column roll forming equipment,

shelf laminate panel roll forming machine,

shelf beam (replacement beam) Cold Roll Forming Machine,

shelf step beam (P beam) automatic roll forming production line,

shelf reinforcement rib roll forming equipment,

shelf label slot roll forming production equipment,

shelf universal Angle steel roll forming production equipment,

shelf bullet beam cold bending forming machine.

shelf column roll forming equipment,

shelf laminate panel roll forming machine,

shelf beam (replacement beam) Cold Roll Forming Machine,

shelf step beam (P beam) automatic roll forming production line,

shelf reinforcement rib roll forming equipment,

shelf label slot roll forming production equipment,

shelf universal Angle steel roll forming production equipment,

shelf bullet beam cold bending forming machine.

This is the engineer's test of the hardness and speed of the machine parts to ensure the high-speed and stable operation of the machine and improve work efficiency

Liming Stamping Form Machine Co.,Ltd. occupies an area of 156,000 square meters and 6 large production plants. It has been established in 1996 with many years of production experience, serving 156 countries, 4 international machinery patents, 10 Chinese machinery patents, nationally certified high-tech company.China's top three steel-building materials equipment factories. Products mainly include trapezoidal steel roof/wall panel machine, C&Z shape purline machine, high-way guardrail machine, sandwich panel production line, deck forming machine, C U L light keel machine, shutter slat door forming machine, cutting machine, Downpipe Machine, Gutter machine, etc.

Warranty: Two years, and we will provide technical support for wholelife of the equipment. If some parts of machine broken within 2 year, we will give customer the spare parts for free. (include chain, bearing, roller,oil pipe, counting wheel) If more than 2 year, maybe some spare parts need to be charged. If machine can not work well, we can teach them online until the machine is perfect. If you need, we can go to your place to assist you. But you need to provide the cost of the engineer.

Packing Method:Main machine is packaged with plastic film. Transportation:All machines need one 40 feet container to hold. Payment Term:30% deposit by T/T in advance and 70% balance after inspection confirmation before shipment. Delivery Time:Within 35 days after receiving deposit.

Q1: Can you customize the machine from your company?

A1: Of course, we can manufacture the machine according to your customized size demand.

Q2: How is the quality? Is there any department related to quality control?

A2: All raw materials we use are quality controlled.Workers will take care of every detail when handling production and packaging. The quality control department is responsible for the quality of each process.

Q3: Is the packaging form?

A3: Yes, of course! All our machines will be packaged in dust and water proof, and they can be reinforced after loading to fully meet export packaging standards.

Q4: How about after-sales service?

Q4: How about after-sales service?

A4: TM is online 24 hours a day, and you can also contact them via email, Skype, MSN, whatsapp.and many more Two-year warranty and parts replacement.

Q5:How to visit your company?

A5:1) Fly to Beijing airport, By high speed train From Beijing Nan to Cangzhou Xi (1 hour).

2)Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours) Then we can pick up you.

Product Categories : Shelf Machine > Shelf board roll forming machine

Premium Related Products

Other Products

Hot Products

TG Car Panel Making Machine Cold Roll Forming Machineangle steel roll forming machine V purin roll forming machinehigh quality cheap supermarket shelves standing pillar roll forming machine made in ChinaRussia hot sell 840 glazed tile forming machine best supplier in Chinahydraulic swing beam nc shearing machine with good price best supplier in ChinaNew Design Automatic high speed light steel keel frame cold roll forming machine made in ChinaColor stone coated roof tile making machine in hebei professional manufacture best pricesBEST 2015 hot sale Solar Photovoltaic Support Roll Forming Machine Metal Stand Forming Machine2015 new arrival downspout roll forming machine,water downspout machine,water pipe machine2015 hot sale! High Speed Floor Deck Roll Forming MachineNew style Door frame roll forming machine door frame equipmentWater gutter roll forming machine, Rain gutter roll forming machine with high qualityHot sell standing seam roof sheet roll forming machine for saleRoll shutter door panel forming machine with high qualityHighway guardrail forming machinery hot saleHigh quality corrugated aluminium metal roof panel roll forming machine