China omega keel roll forming machine with servo motor steel frame

Product Description

Products Description

Product Description

China Omega keel Roll Forming Machine with servo motor steel frame

Introduction

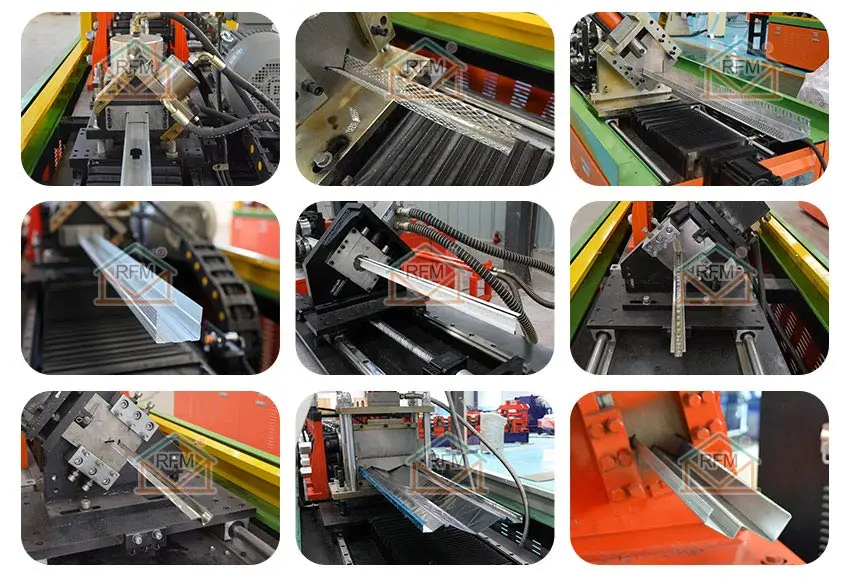

The forming process of our furring channel keel forming machine is made by copra software. We have a professional design team and design software. Our engineers have gone to the copra software research and development center to study, so we can use copra software to calculate the molding process required for furring channel very professionally, and the entire molding process is supported by data and accurate The degree is very high.

1.This roll forming machine can rollform metal roofing sheet. After roll formed by this roll forming machine, the surface will be very smooth and beautiful without any scratch on surface. 2.Rollforming process:uncoiler, rollforming, forming step effect, cut to length. 3.Fully Automatic Control System with PLC. 4.Easy operation: Key in the length and quantity on the control panel. 5.Two years warranty. 6.we also can do a custom roll forming machine, We can design the machine according to your specification and profile drawing. 7.One roll forming machine only can produce one profile.

Specifications

After-sales Service Provided | Field maintenance and repair service, Video technical support |

Product’ sizes | According to customer’s request |

Processing material | GI |

Processing thickness | 0.3-0.7mm |

Quantity of roller stations | 12 |

Production speed | Approximate 15-25 m/min |

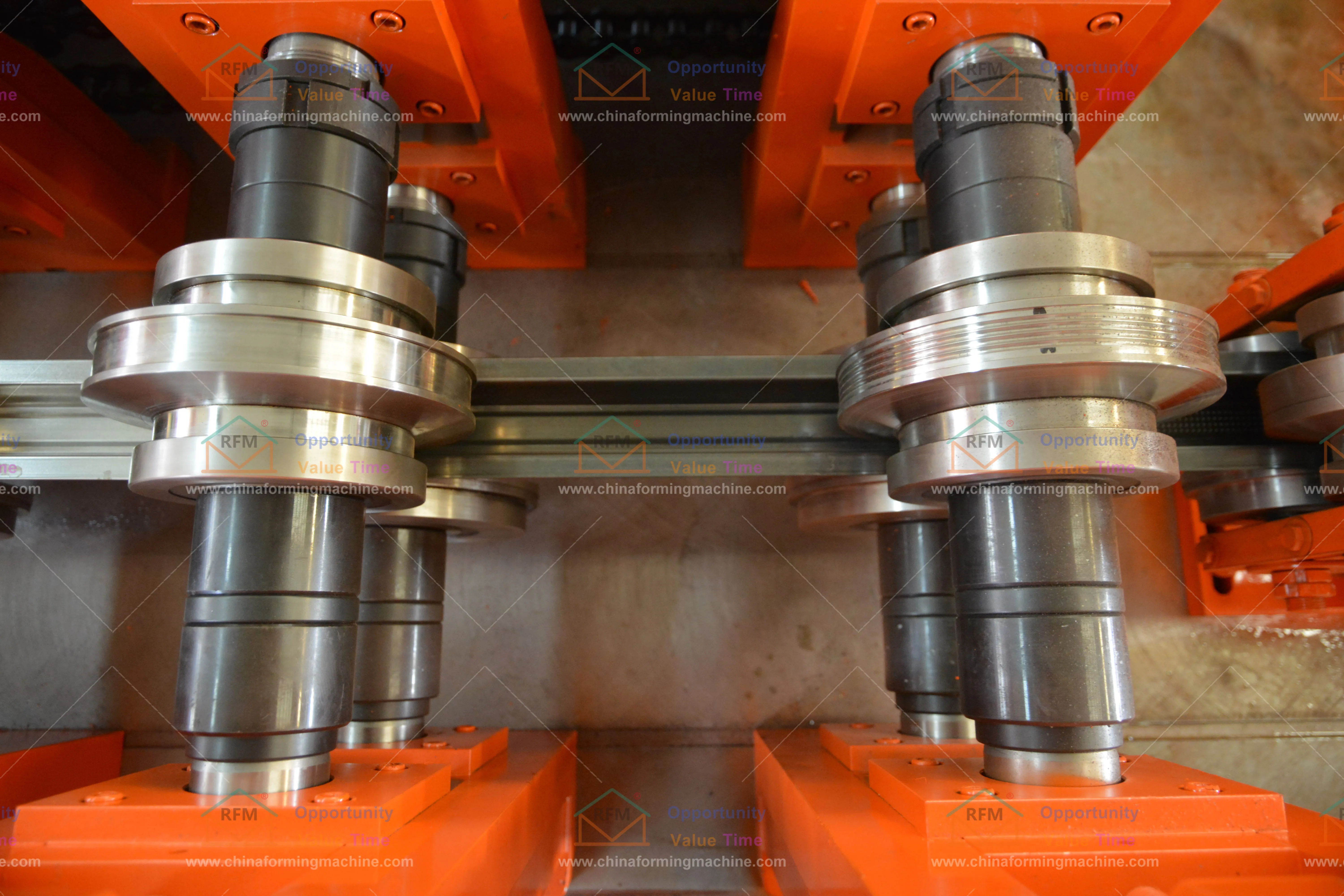

Diameter of shafts | Φ40mm |

Material of rollers | Cr12 steel with vacuum heat treatment HRC57°-60° |

Material of shafts | 45# steel quenched and tempered |

Material of cutting blades | Cr12 mould steel with quenched treatment |

Size of machine | Approximate 4000mm(L)×900mm(W)×1300mm(H) |

Theoretical weight | Approximate 2000KGS |

Driven method | Chain transmission |

Brand of PLC | Delta |

Cut mode | Hydraulic profile cutting |

Power supply | 380V 50HZ 3Phases or at buyer’s requirement |

Rollers

High quality rollers will help to produce the beautiful and high quality profile. That will satisfy your customers.

Using high qualiy thick shaft, the strength is more durable

European-style electric control cabinet

We adapt the PLC for the control system, it will be so much helpful for users to handle the machine. The control system will be in charge of the working condition like the speed, cutting length and cutting quantity. The display screen will be the touch screen or the text screen, the language can be English, or as required.

Related products

Related Products

As the original manufacturer of the tile press, we can produce most of the products according to your requirements, not just the size of the products on this page.

Company Profile

Company Profile

Liming Stamping Form Machine Co.,Ltd. occupies an area of 156,000 square meters and 6 large production plants. It has been established in 1996 with many years of production experience, serving 156 countries, 4 international machinery patents, 10 Chinese machinery patents, nationally certified high-tech company.China's top three steel-building materials equipment factories. Products mainly include trapezoidal steel roof/wall panel machine, C&Z shape purline machine, high-way guardrail machine, sandwich panel production line, deck forming machine, C U L light keel machine, shutter slat door forming machine, cutting machine, Downpipe Machine, Gutter machine, etc.

Cooperative Partners

Cooperative Partners

After-Sales Service

After-Sales Service

We have a complete after-sales service system, two years, and we will provide technical support for wholelife of the equipment.engineers can come to service training and maintenance.Our machine( Omega keel machine ) has a long service life, simple operation and easy to use, we provide network after-sales service for life. A strong behind-the-scenes team makes your purchase worry-free.

FAQ

Q: Can you customize the machine from your company? A: Of course, we can manufacture the machine according to your customized size demand.

Q: How is the quality? Is there any department related to quality control? A: All raw materials we use are quality controlled. Workers will take care of every detail when handling production and packaging. The quality control department is responsible for the quality of each process.

Q: Is the packaging form? A: Yes, of course! All our machines will be packaged in dust and water proof, and they can be reinforced after loading to fully meet export packaging standards.

Q: How about after-sales service? A: TM is online 24 hours a day, and you can also contact them via email, Skype, MSN, whatsapp. and many more Two-year warranty and parts replacement.

Packing&Shipping

Packing & Shipping

1 Standard exported package: Internal anticollision protection, external export wooden box packaging. 2 Shipping by express, by sea according to customers' requirements to find the most suitable way. 3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Product Categories : Stud and Track roll forming machine > Omega profile roll forming machine

Other Products

Hot Products

TG Car Panel Making Machine Cold Roll Forming Machineangle steel roll forming machine V purin roll forming machinehigh quality cheap supermarket shelves standing pillar roll forming machine made in ChinaRussia hot sell 840 glazed tile forming machine best supplier in Chinahydraulic swing beam nc shearing machine with good price best supplier in ChinaNew Design Automatic high speed light steel keel frame cold roll forming machine made in ChinaColor stone coated roof tile making machine in hebei professional manufacture best pricesBEST 2015 hot sale Solar Photovoltaic Support Roll Forming Machine Metal Stand Forming Machine2015 new arrival downspout roll forming machine,water downspout machine,water pipe machine2015 hot sale! High Speed Floor Deck Roll Forming MachineNew style Door frame roll forming machine door frame equipmentWater gutter roll forming machine, Rain gutter roll forming machine with high qualityHot sell standing seam roof sheet roll forming machine for saleRoll shutter door panel forming machine with high qualityHighway guardrail forming machinery hot saleHigh quality corrugated aluminium metal roof panel roll forming machine