High frequency steel panel round pipe roll forming machine for rain spout

Basic Info

Model No.: TG-Downpipe

Product Description

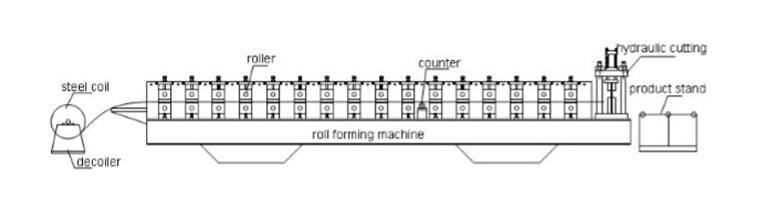

Manual De-coiler --- Electric Feeding --- Servo motor feeding ----oll Forming Machine------Computer Control Cabinet---Automatic cutting Mechanism ---Run-out Tables 2. The equipment including

Manual De-coiler --- Electric Feeding --- Servo motor feeding ----oll Forming Machine------Computer Control Cabinet---Automatic cutting Mechanism ---Run-out Tables 2. The equipment including 1 set | |

Hydraulic cutter | 1 set |

Electrical control system | 1 set |

Hydraulic system | 1 set |

Normal run out table | 1 PC 1m*1m |

Manual de-coiler | 1 set Max. loading 5 T |

(2) Roll forming machine

(2) Roll forming machine Description | ||

Product Name | ||

Machine Size | 6000mm*800mm*1200mm | |

Machine Weight | About 4 T | |

Frame Materials | 350H section steel | |

Middle plate thickness | 12mm | |

Forming Shaft | Diameter | 70mm |

Material | 45# quenched and tempered material | |

Forming roller | 45# Forging Hard Chrome Plating | |

Drive mode | 1 inch sprocket, chain | |

Forming Station | 18 stations | |

Forming Speed | 8-12m/min | |

Pressing Thickness | 0.2-0.9mm | |

Pressing width | ≤400mm | |

Main Engine Power | 7.5KW with cycloidal reducer | |

Pump Station Motor | 3KW | |

Computer | Taiwan “Delta” | |

Coder | Wuxi "rip" or "Xin Ya" | |

Switch | " CHINT "or" delixi" | |

(3) Hydraulic Cutting 1) Adopts post cutting, Stop to cut; 2) The cutting blade material is Cr12 with quenched treatment. 3) Adopts welded frame for good rigidity. 4) Cutting frame has been heat treatment to avoid final product deformation. cutting length tolerance ±2mm. 5) The power of cutting is provided by hydraulic station. 6) The final product can be cut as per set length in PLC controller, and the length is automatically measured by encoder. When final product reaches the set length, machine will stop to cut the Product automatically. Finish this action, machine will run again continuously. (4) Hydraulic station 1) It supplies the power for the hydraulic cutter. 2) All hydraulic accessories are all use Chinese famous brand products. 4) Hydraulic motor power: 3KW Hydraulic station for reference:

(3) Hydraulic Cutting 1) Adopts post cutting, Stop to cut; 2) The cutting blade material is Cr12 with quenched treatment. 3) Adopts welded frame for good rigidity. 4) Cutting frame has been heat treatment to avoid final product deformation. cutting length tolerance ±2mm. 5) The power of cutting is provided by hydraulic station. 6) The final product can be cut as per set length in PLC controller, and the length is automatically measured by encoder. When final product reaches the set length, machine will stop to cut the Product automatically. Finish this action, machine will run again continuously. (4) Hydraulic station 1) It supplies the power for the hydraulic cutter. 2) All hydraulic accessories are all use Chinese famous brand products. 4) Hydraulic motor power: 3KW Hydraulic station for reference:  (5) PLC Control System 1) This system uses Delta PLC to control the all working actions. Production quantity and each piece length will be automatically measured. It is convenient to control the roll forming machine. 2) Delta converter adjusts speed technology, realize the automatic production. 3) Text screen is input and cancelled the working data. 4) Friendly man-machine interface system can be set batches to the work piece, length, quantity, etc. 5) Encoder count, having function of count and measuring length. 6) Suitable power voltage: 380V/50HZ/3Phase (can de designed according to buyer’s requirement) (6) Product Rack (un-powered) 1) They are used to put the final product when product coming out from cutting device. 2) Two pieces, each piece length is 1m, total length is 3 meters. 3) Collect the final product and final products are convenient to be stacked by workers. 5.Equipment Details.

(5) PLC Control System 1) This system uses Delta PLC to control the all working actions. Production quantity and each piece length will be automatically measured. It is convenient to control the roll forming machine. 2) Delta converter adjusts speed technology, realize the automatic production. 3) Text screen is input and cancelled the working data. 4) Friendly man-machine interface system can be set batches to the work piece, length, quantity, etc. 5) Encoder count, having function of count and measuring length. 6) Suitable power voltage: 380V/50HZ/3Phase (can de designed according to buyer’s requirement) (6) Product Rack (un-powered) 1) They are used to put the final product when product coming out from cutting device. 2) Two pieces, each piece length is 1m, total length is 3 meters. 3) Collect the final product and final products are convenient to be stacked by workers. 5.Equipment Details.

6. Factory overview

6. Factory overview  7. Foreign Customers

7. Foreign Customers

8. Authentication

8. Authentication  9. Payment terms and after-sale service: 1) FOB Tianjin 2) Payment: 30% T/T deposit, and pay the balance before shipping. 3) Delivery time: 30 working days. 4) Guarantee period: 12 months limited warranty starting from date of delivery. Shipping cost for parts to be replaced during warranty period have to be borne by the customer. 5) Spare parts: bearings, buttons, chains, magnetic valve, protective tube etc. 6) Installation and training: 1. If buyers visit our factory and check the machine, we will teach you how to install and us the machine, and also train your workers/technician face to face. 2. Without visiting, we will send you user manual and CD to teach you to install and operate. 3. COST OF INSTALLATION: The buyer should pay the installation charges (USD 100 one man one day). To the seller’s appointed account by T/T before the seller’s technicians go to the buyer’s factory. The buyer pays the seller’s technicians travel cost outside China, including round air tickets fee, accommodation and food, provide transportation from living hotel to the work place, necessary communication, and insurance, etc. If you have any further question of our Equipment, please feel free to contact me, thanks! Contact us if you need more details on Steel Panel Round Pipe Roll Forming Machine for Rain Spout. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Steel Panel Round Pipe Roll Forming Machine、Roll Forming Machine for Rain Spout. If these products fail to match your need, please contact us and we would like to provide relevant information.

9. Payment terms and after-sale service: 1) FOB Tianjin 2) Payment: 30% T/T deposit, and pay the balance before shipping. 3) Delivery time: 30 working days. 4) Guarantee period: 12 months limited warranty starting from date of delivery. Shipping cost for parts to be replaced during warranty period have to be borne by the customer. 5) Spare parts: bearings, buttons, chains, magnetic valve, protective tube etc. 6) Installation and training: 1. If buyers visit our factory and check the machine, we will teach you how to install and us the machine, and also train your workers/technician face to face. 2. Without visiting, we will send you user manual and CD to teach you to install and operate. 3. COST OF INSTALLATION: The buyer should pay the installation charges (USD 100 one man one day). To the seller’s appointed account by T/T before the seller’s technicians go to the buyer’s factory. The buyer pays the seller’s technicians travel cost outside China, including round air tickets fee, accommodation and food, provide transportation from living hotel to the work place, necessary communication, and insurance, etc. If you have any further question of our Equipment, please feel free to contact me, thanks! Contact us if you need more details on Steel Panel Round Pipe Roll Forming Machine for Rain Spout. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Steel Panel Round Pipe Roll Forming Machine、Roll Forming Machine for Rain Spout. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Downpipe Roll Forming Machine